Team Armec’s journey in convincing the sugar mills for going for water conservation and water management across globe has been very interesting.

In early nineties our leader Mr Bhagawan Harani visited and interacted with more than 50 sugar mills ( across India and abroad ) mainly to promote the jet technology cooling towers for Boiling house injection water cooling .

During all this interaction what he found was bit shocking.

- Sugar cane has more than 70 % water and everyone in the industries knew this very well.

- Ground water use with the help of boring pumps was norm in most of the factories.

- Continuous power was used for water pumping.

- The water content in sugar at the end of boiling house used to get manifested as excess condensate ( after use and reuse )

- This condensate was basically condensed steam , but with dissolved gases.

- For sugar mills this was not usable water, as they found very high temperatures of 90 degree C and above as limiting factor.

- Water treatment was totally avoided due to very high temperatures.

- Most of the time, this excess condensate water was drained out and totally wasted.

- There was no culture of water conservation or water management as sugar mills were purely an agri industries and within the fraternity there were even lucky sugar mills which had an irrigation canal either passing through the mill or next to the mill.

- Still team Armec under the guidance of Mr Bhagawan Harani started requesting every one to reuse this water.

- Initially for first few years there was general rejection of the concept as many laughed on the need of water conservations when they had more pressing problems. Few thought Armec is trying to push some products. We were trying to promote jet technology for boiling house and power generation where huge amount of investment on continuous basis was done in conventional cooling system . The irony was that all the crores of rupees invested were only utilised for 4 to 6 months only ( as sugar mills have limited production time cycle ).

- Few technocrats did like the idea but budgetary support was a problem.

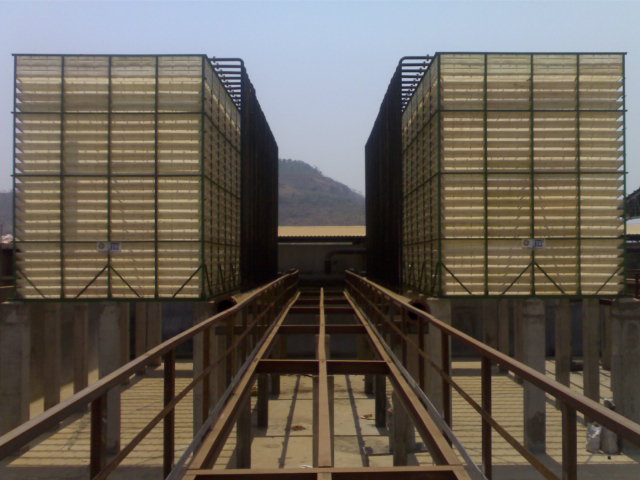

- Team Armec worked out a very beautiful two stage cooling where in first stage was by gravity flow and second stage was with very low head pump. An innovative water balancing scheme was also launched which eliminated costly instrumentation support system .

- Once the initial cost and running cost was brought down , people started pushing this kind of project more as an individual initiatives within sugar fraternity.

- It took more than a decade to establish this kind of water conservation drive on larger scale.

- First they laugh at you , then they listen you , then they realise , then they start helping themselves !!

- By 2016 “ water saving , water conservation and water management have become catchy slogans !

- Water recycling is e now a compulsory subject for sugar mills. They can no more waste or disrespect water use. Zero discharge is becoming a reality mainly because of law (and not out of love for mother nature ! )

- Today not a single sugar factory can be planned without excess condensate cooling system.

What we started was a small drive but today it has become a global movement.